Stratus: Extreme Hiking Footwear

About the Design

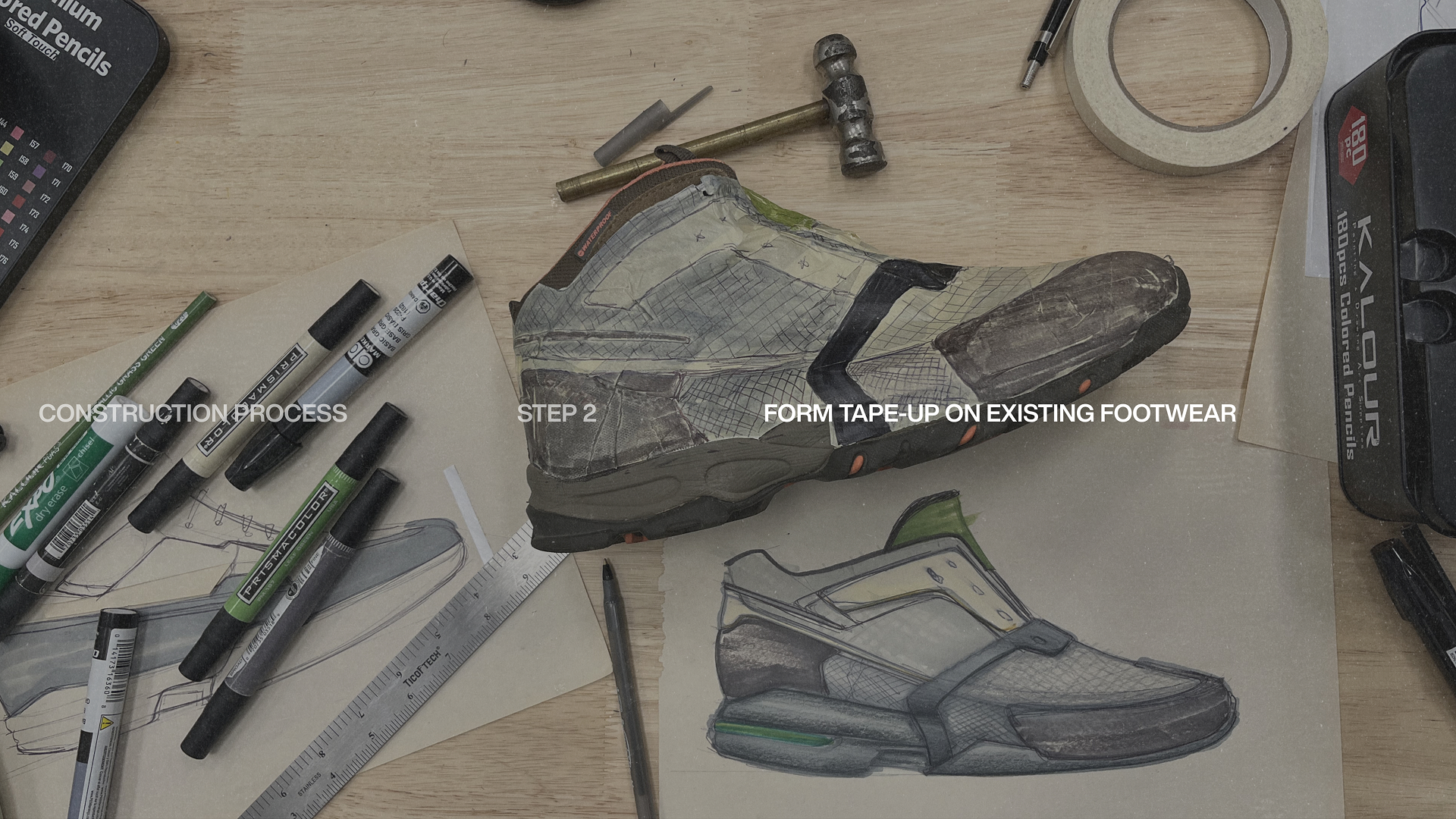

In collaboration between Industrial Designer, Srivats Srinivasan, we were able to bring both of our skills together to successfully design and fabricate this footwear design. While this was a team effort to ideate and decide on the final design direction, Srivats was in charge of the 3D modeling & CAD for the project and I (Will Gates II) was in charge of the sketching and fabrication of the upper & assembly of the shoe.

This design is the future of hiking footwear and takes 3D printed footwear and ergonomics where it has never gone before for the ultimate perfomance hiking boot.

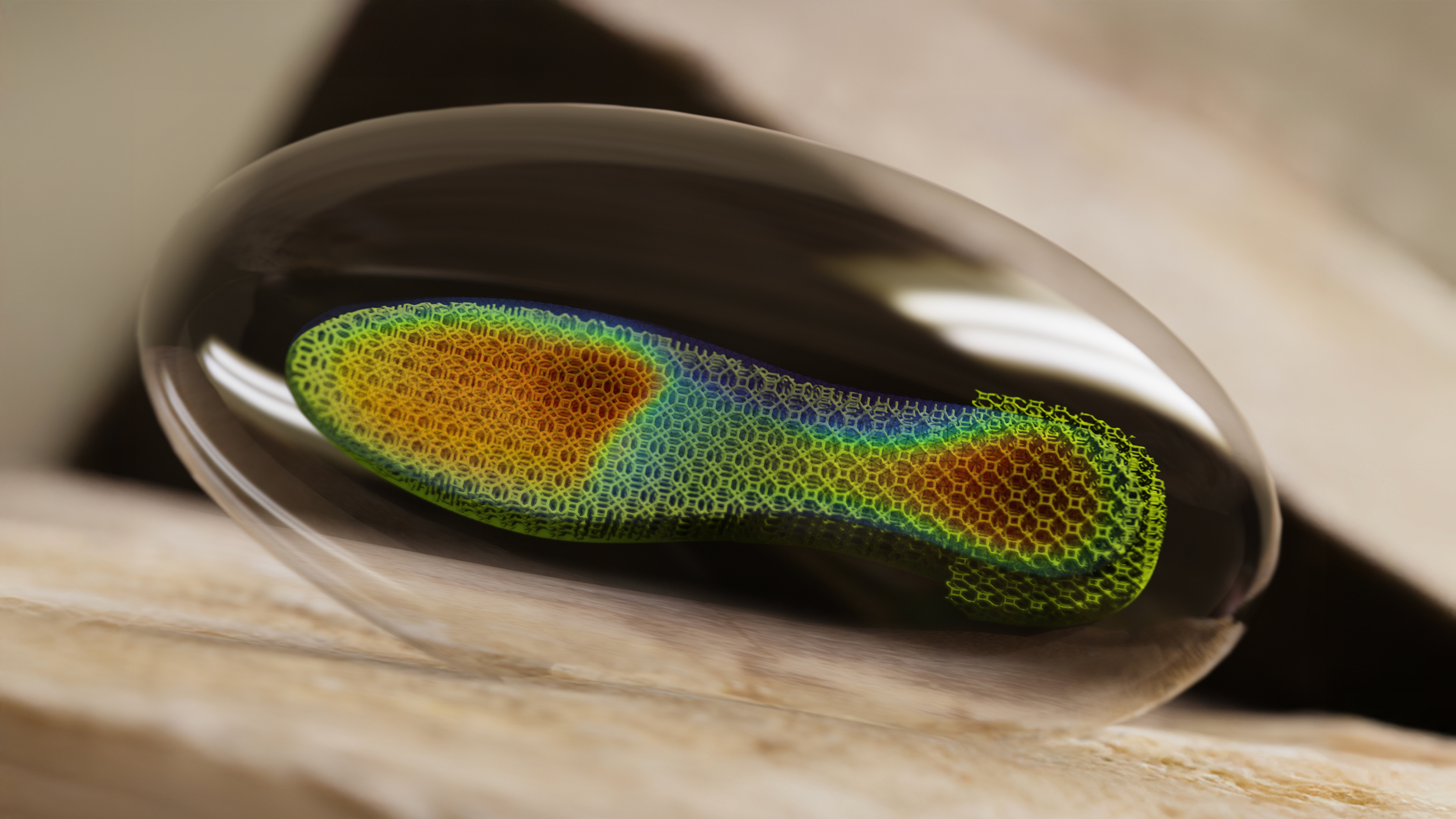

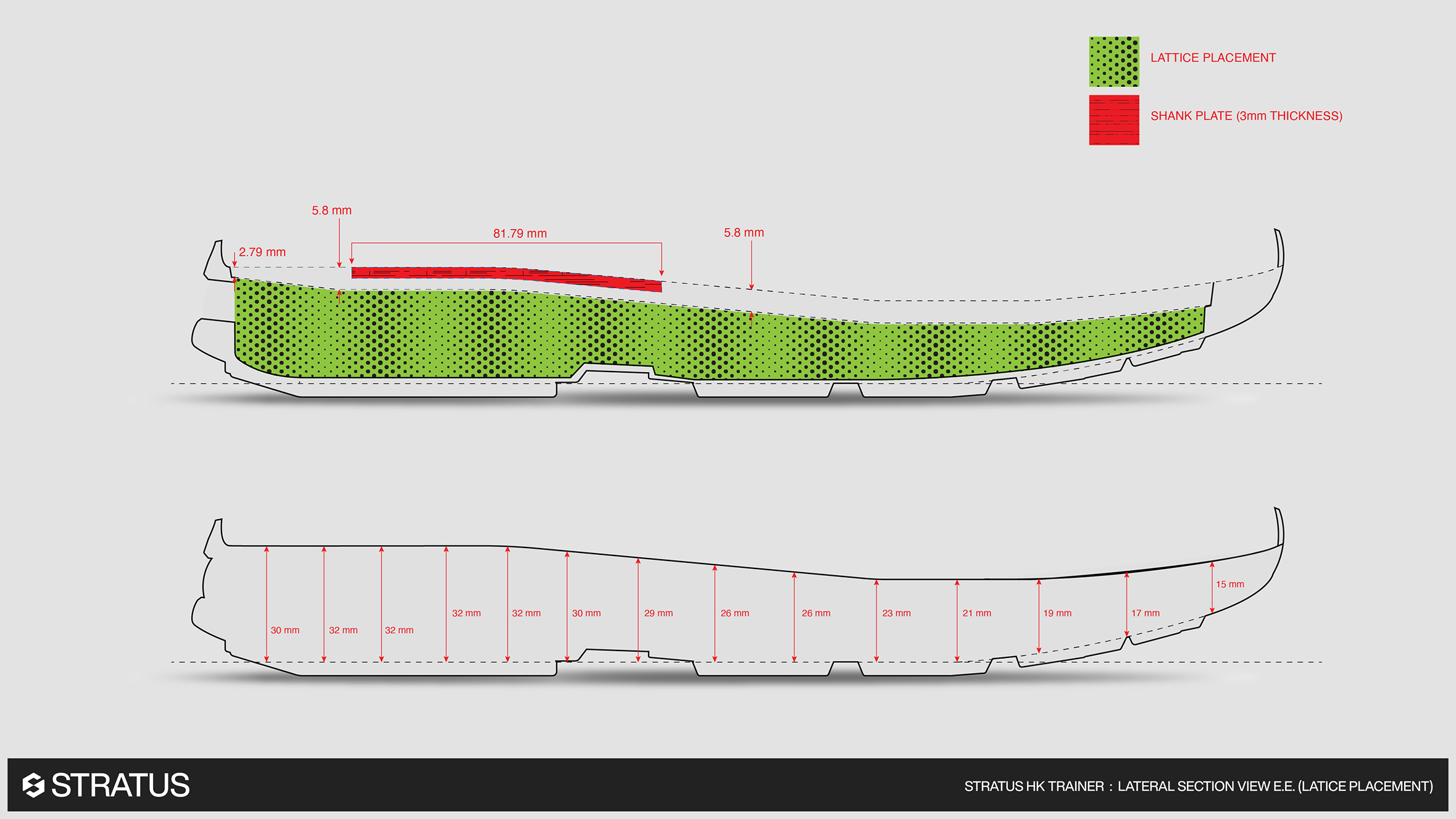

Lattice Cushioning Technology

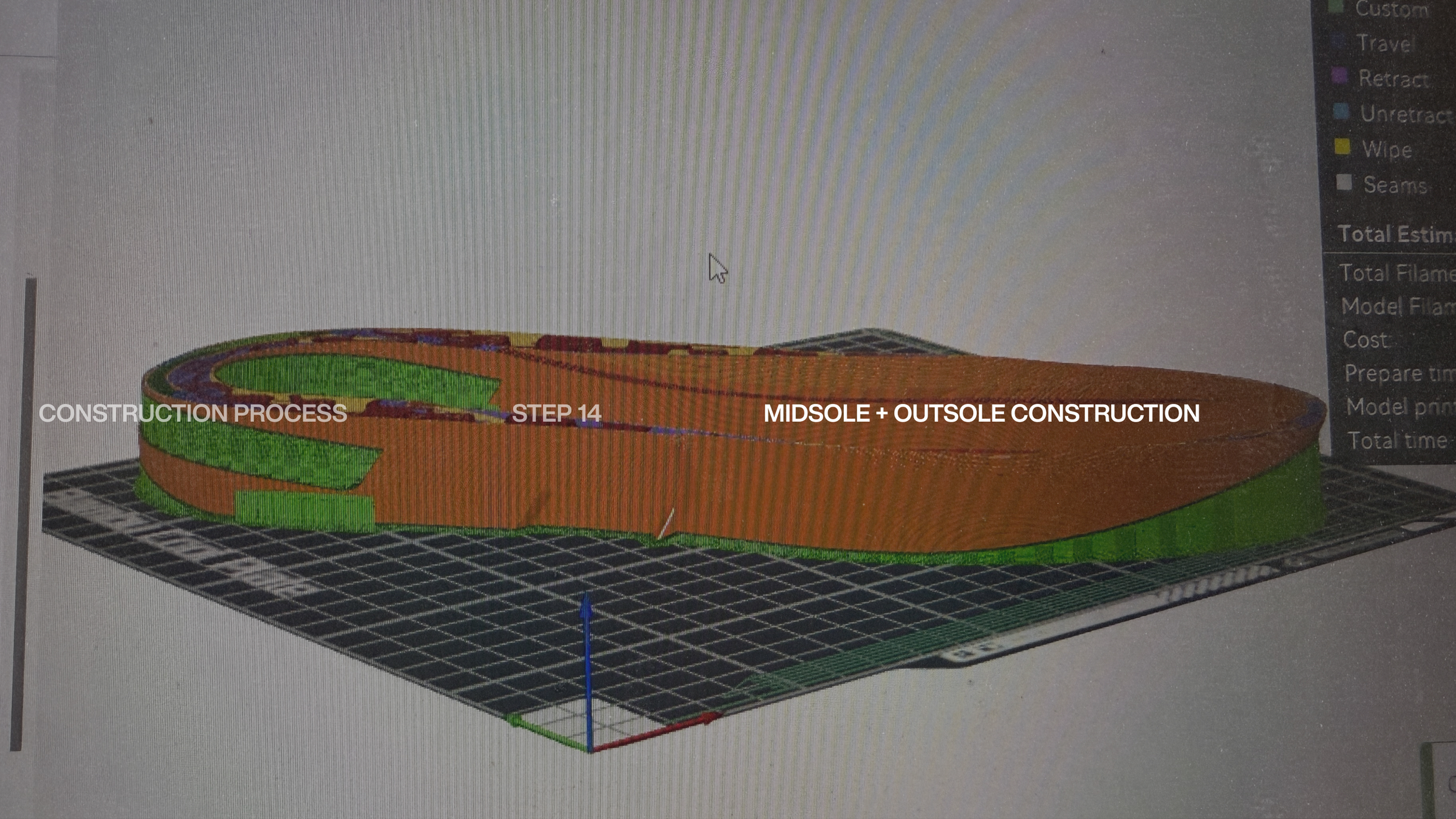

Using pressure-map data from the impact of the extreme hiker, we were able to design a full length, lattice cushioning pod. The different types of lattice flow seamlessly within the pod for the perfect balance of cushioning and support.

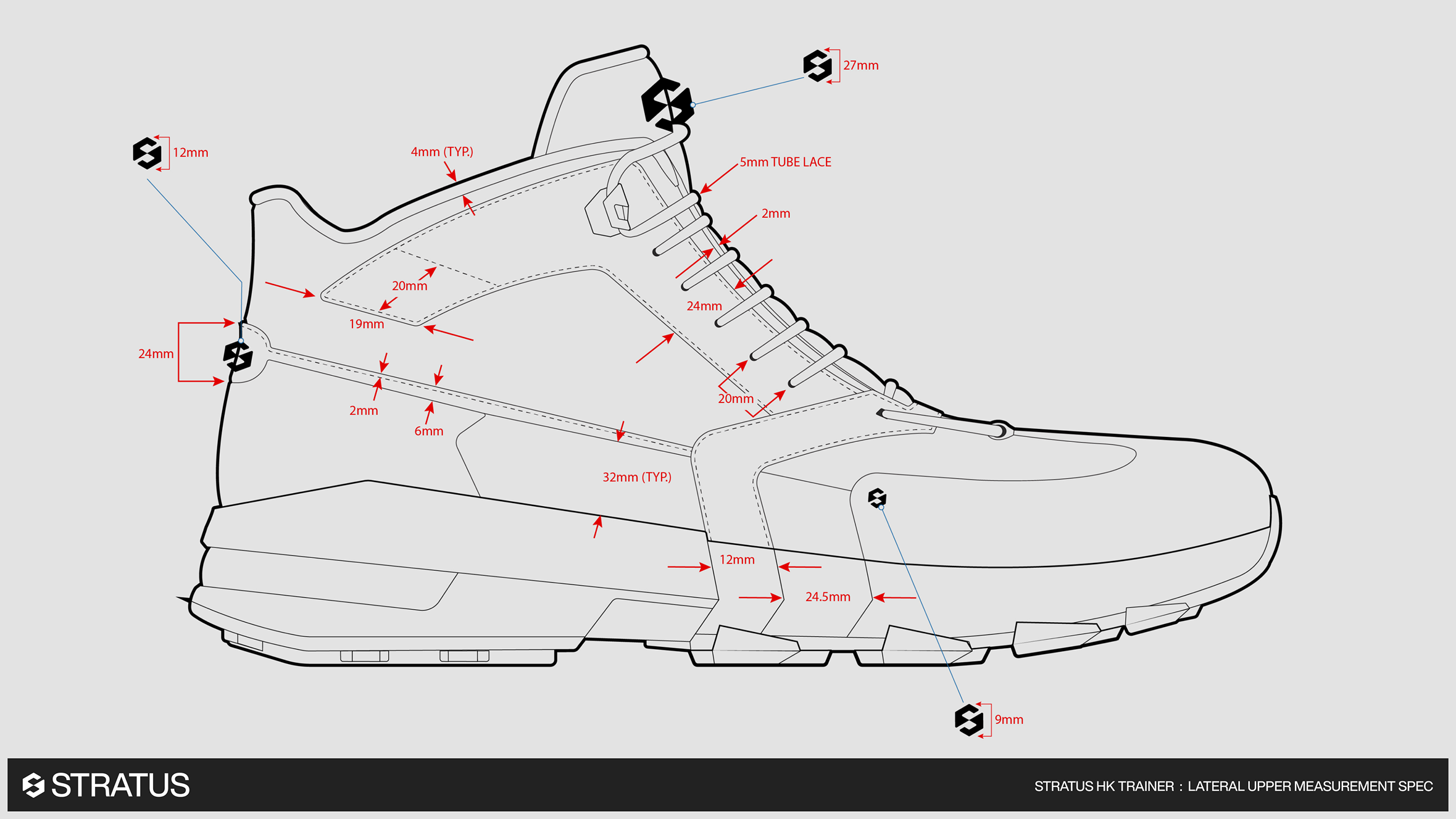

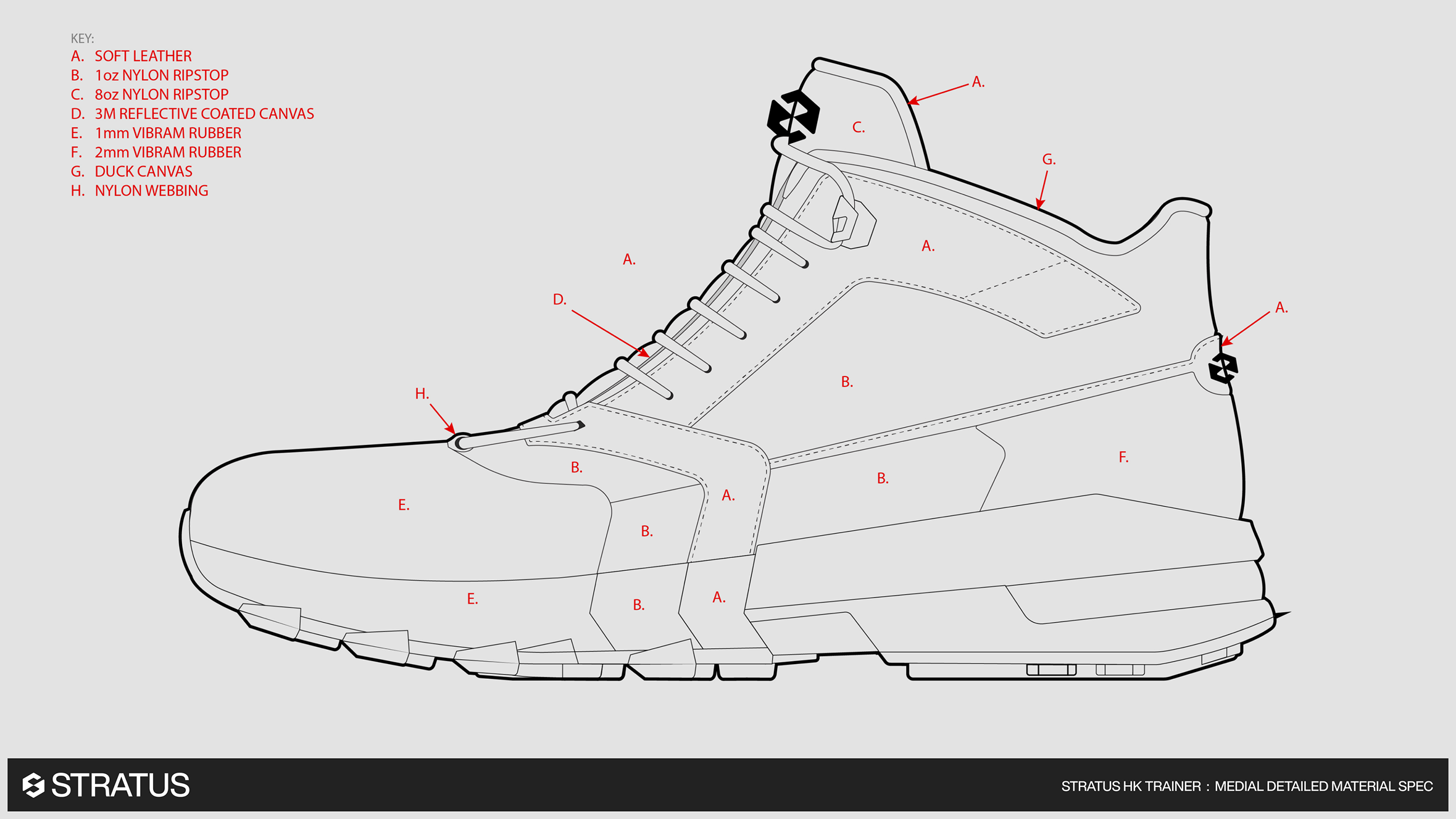

Tech Pack

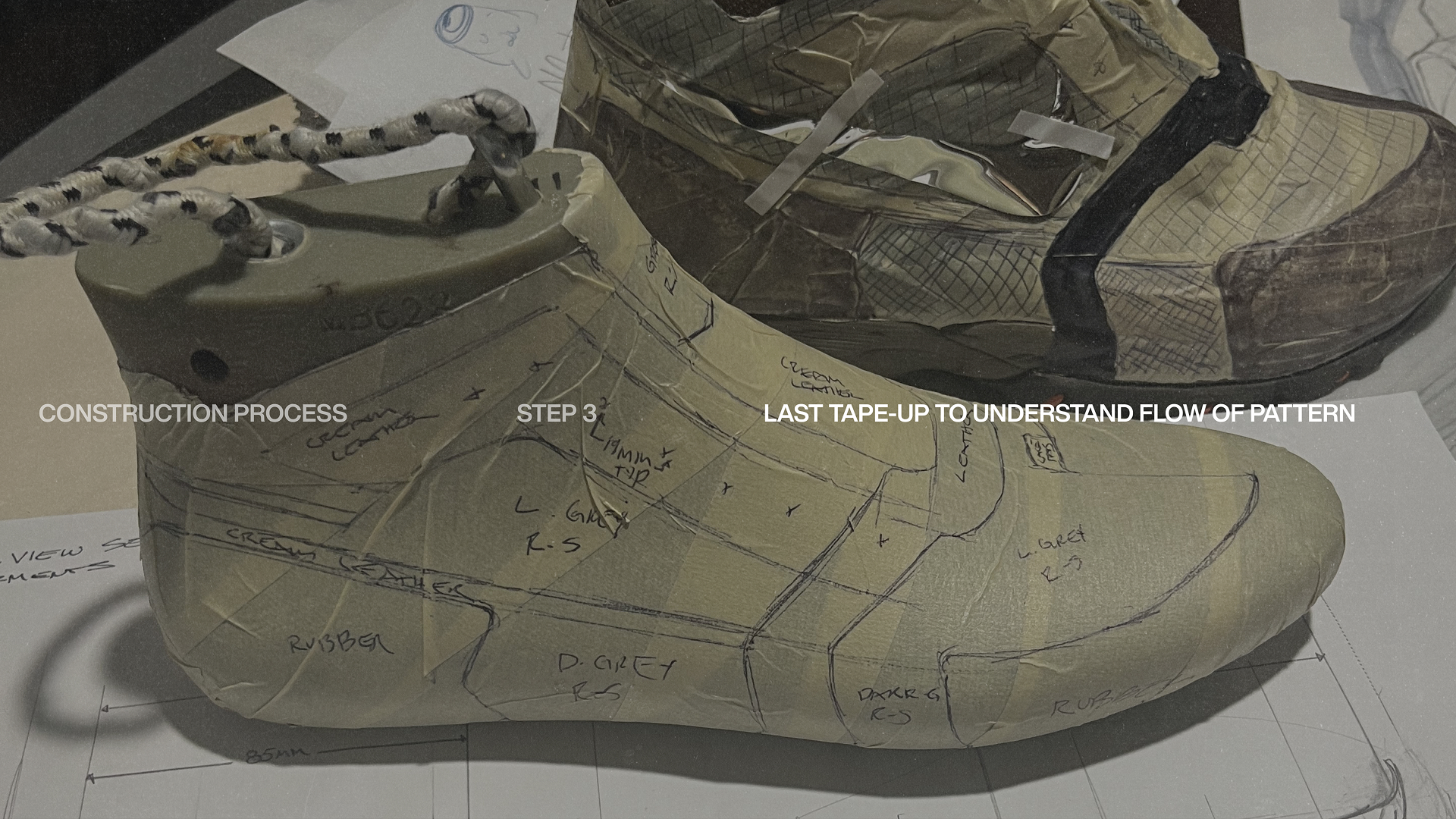

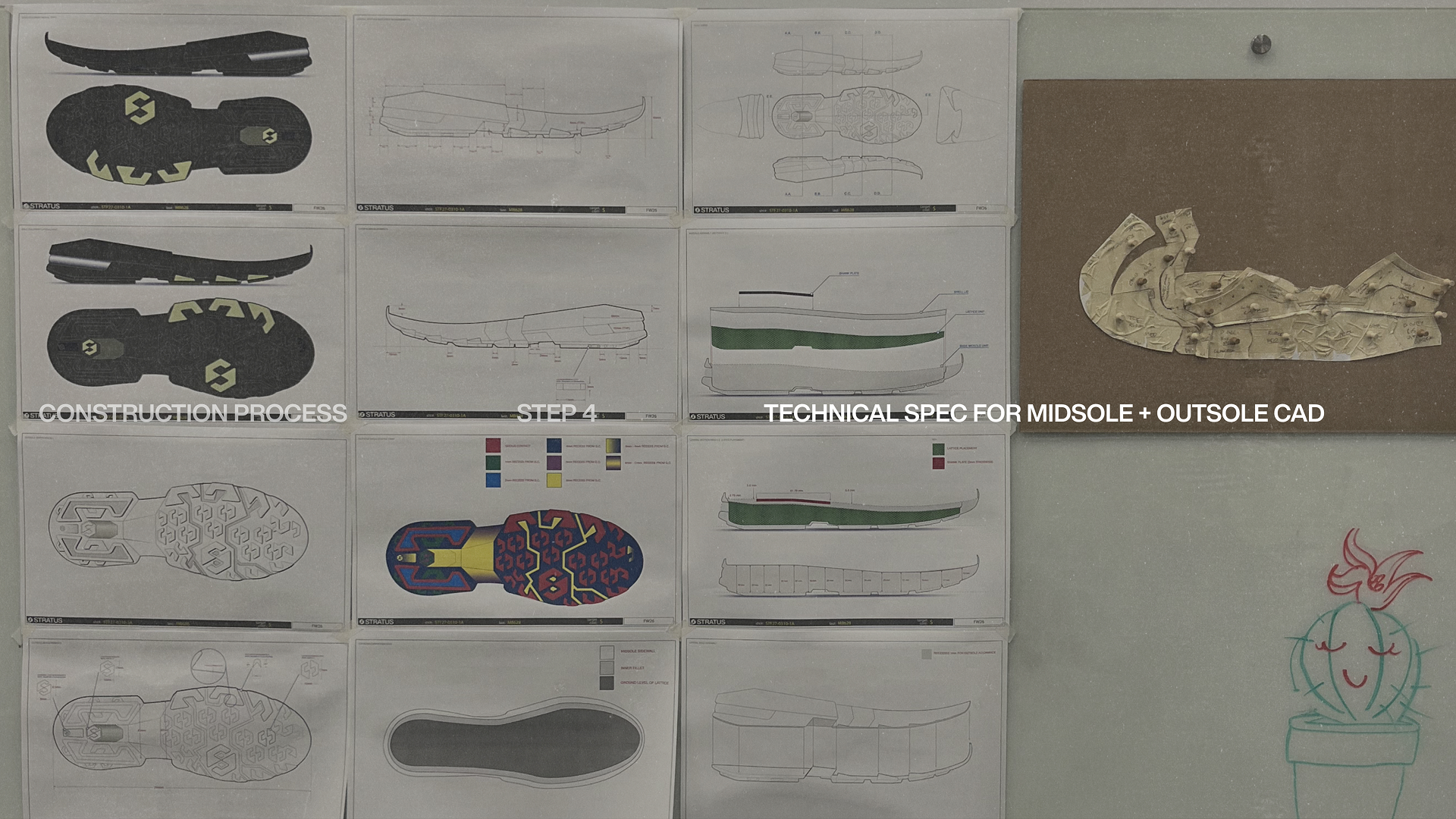

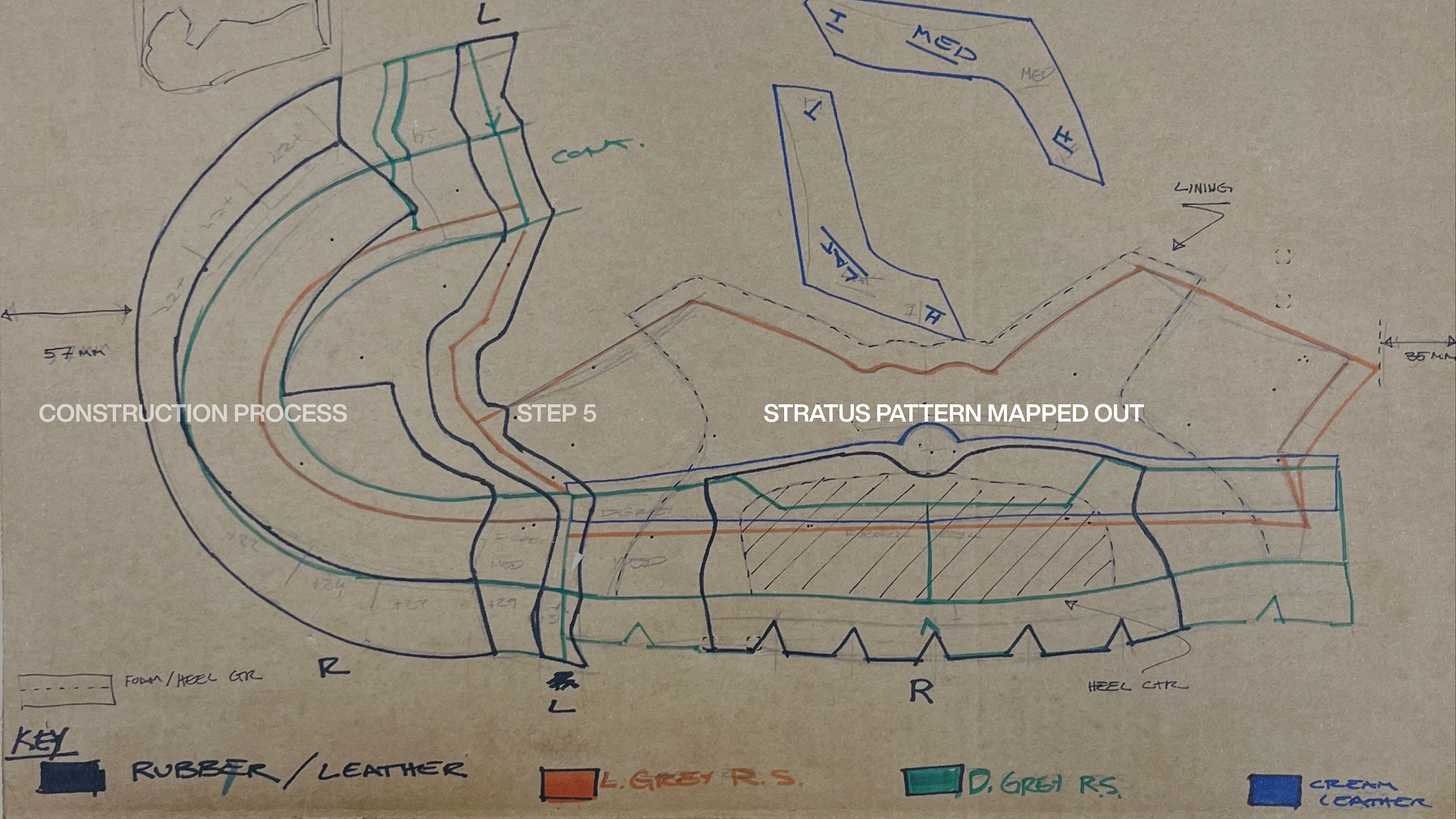

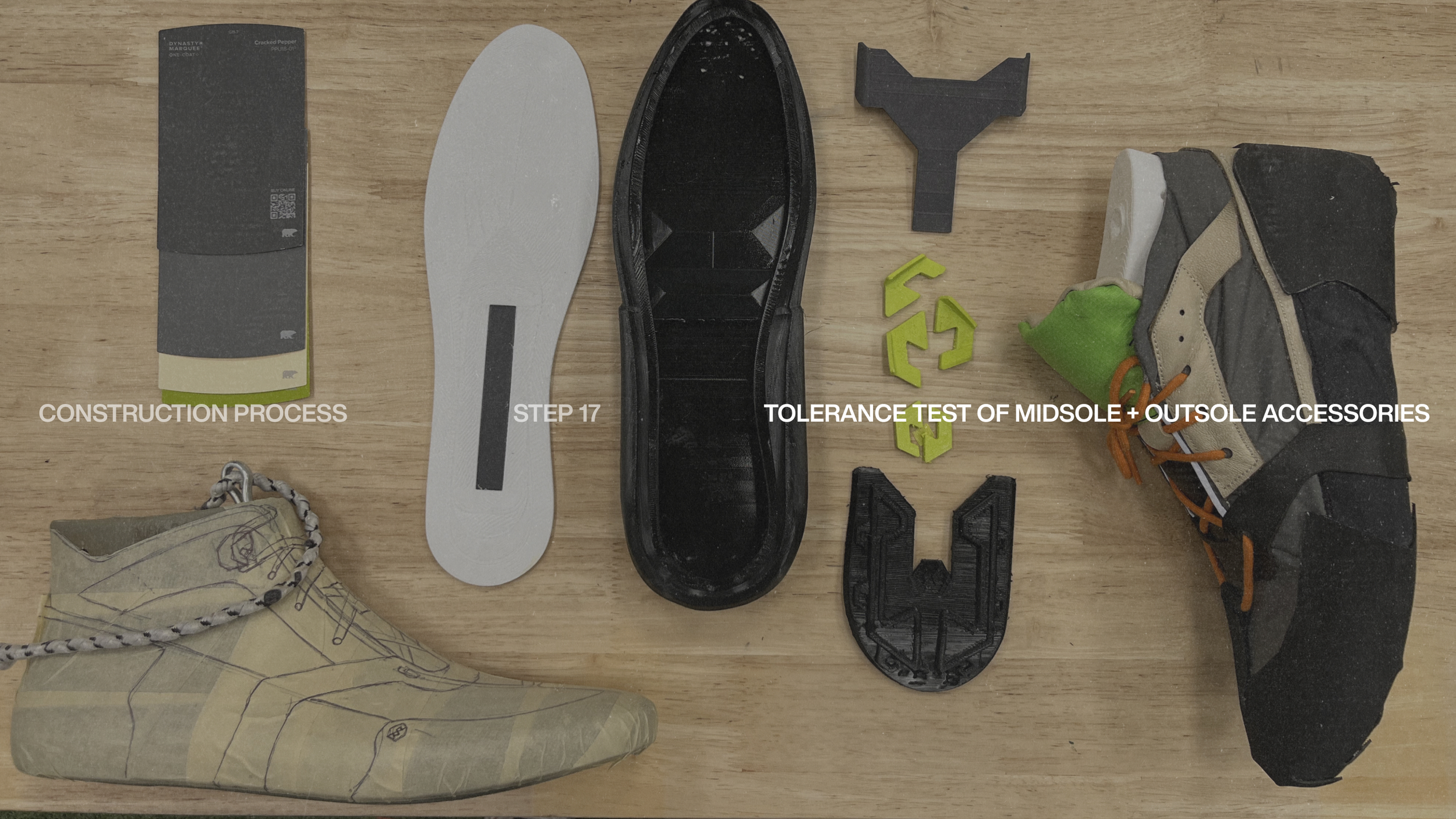

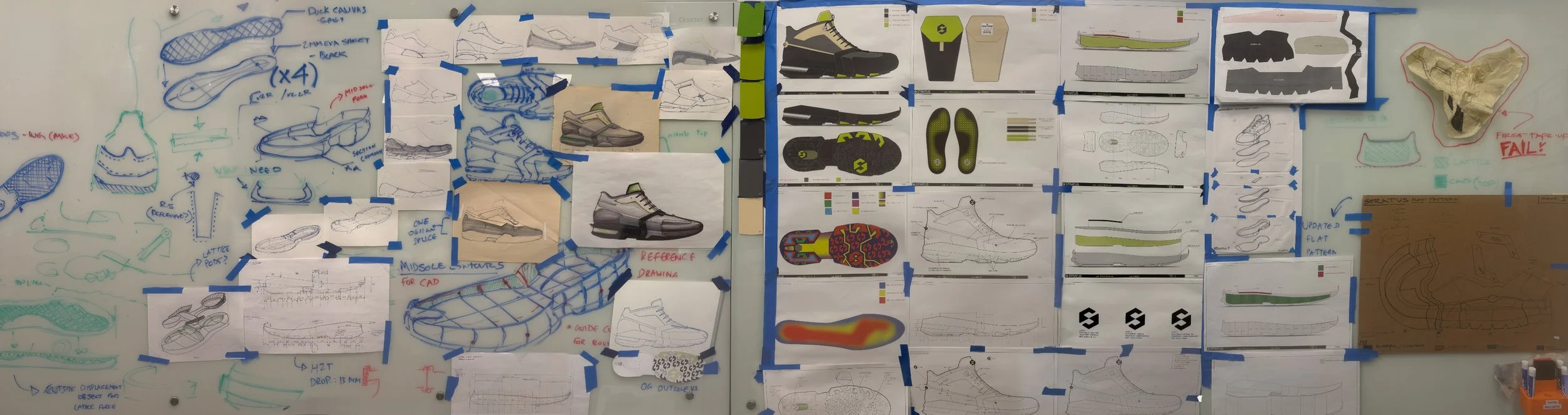

Raw Process

Gallery

Design Process

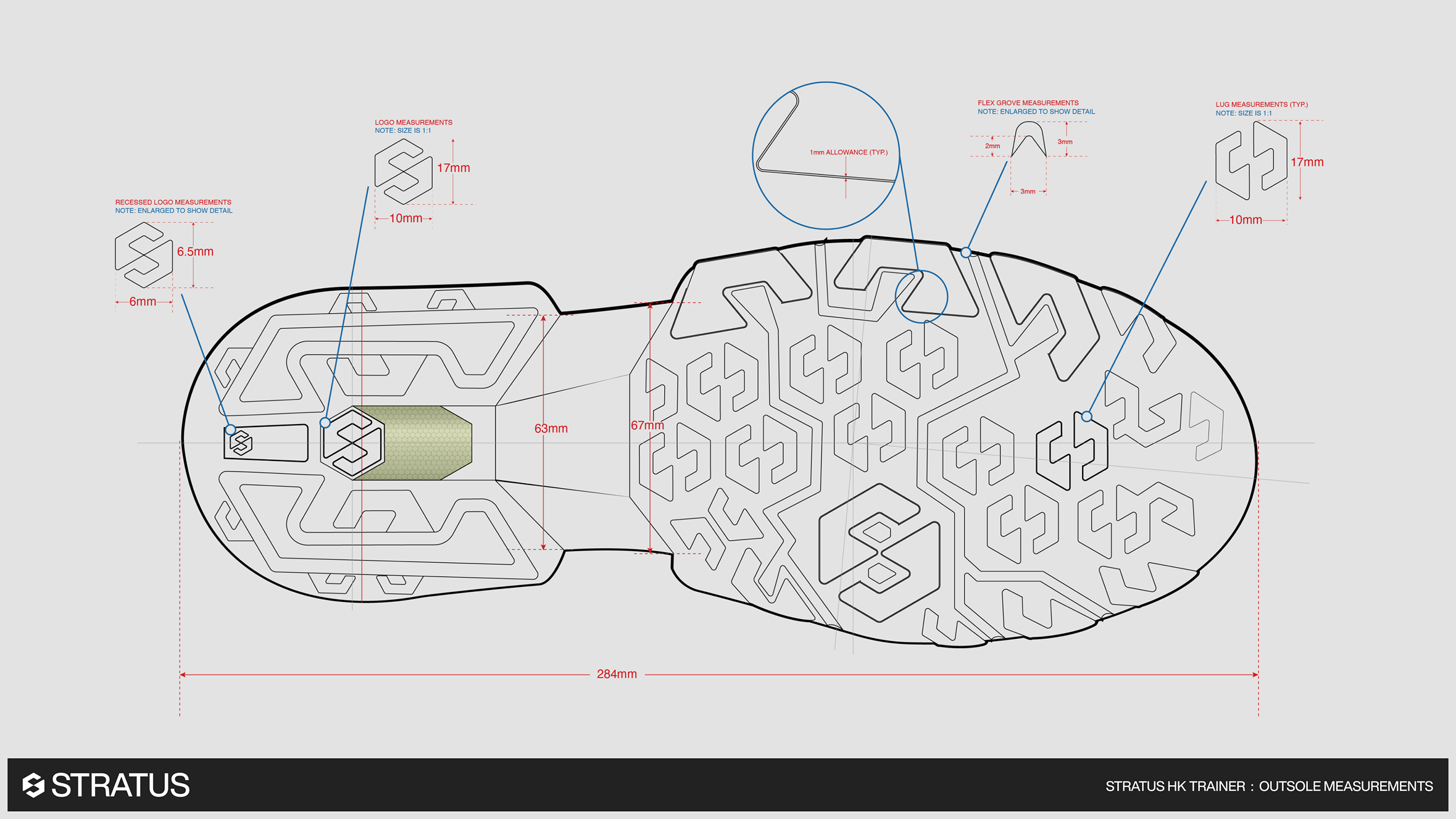

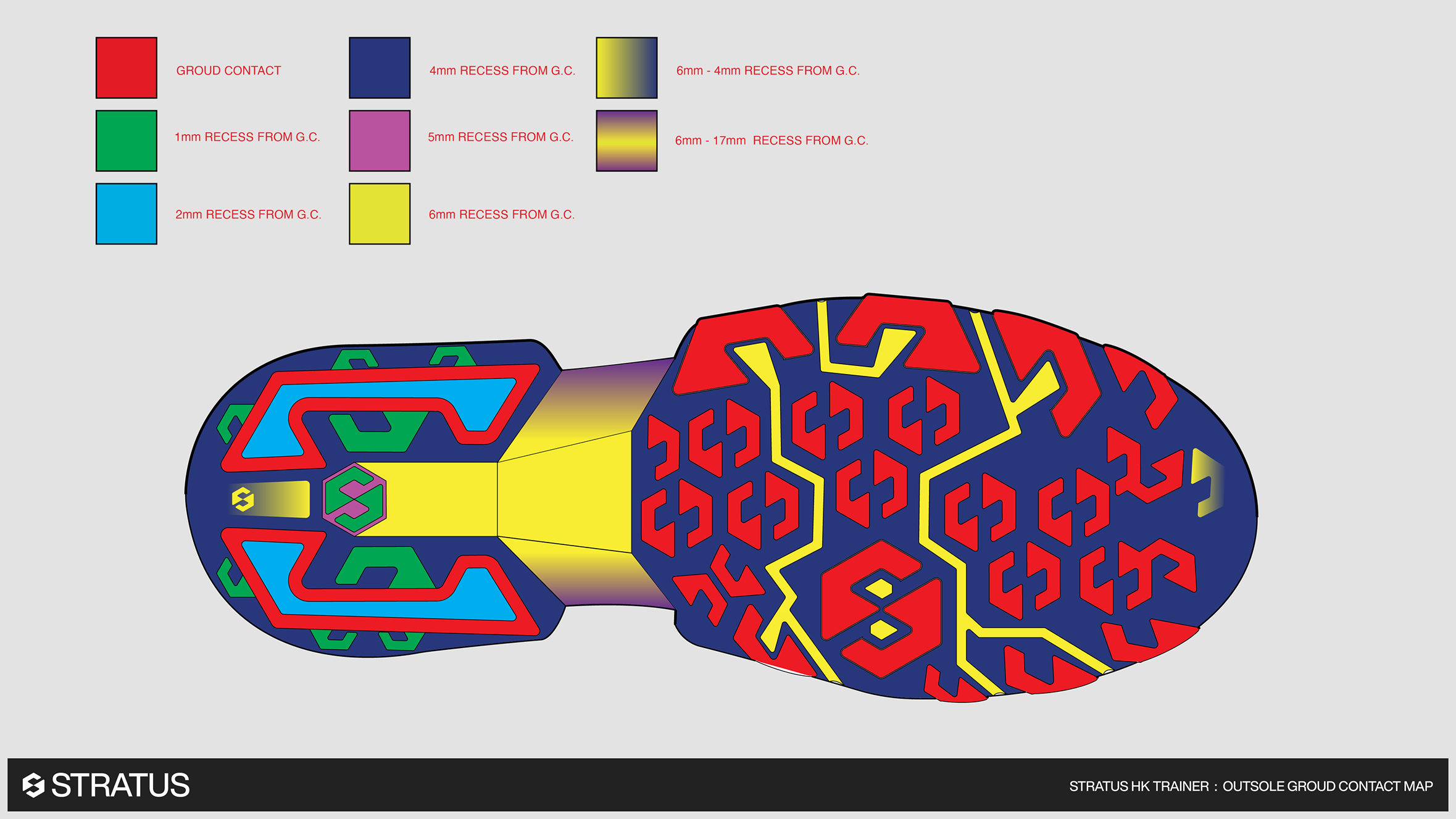

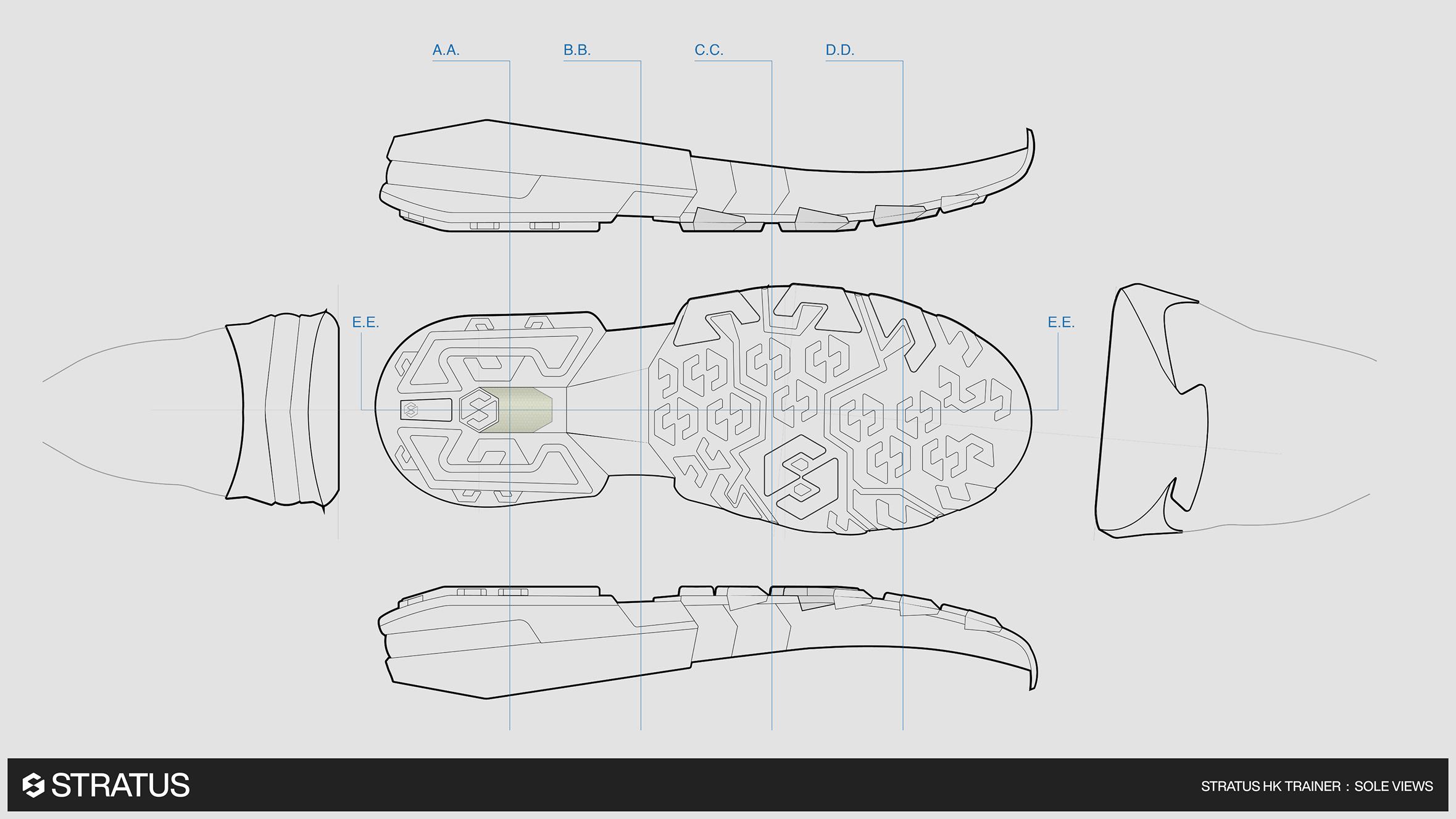

Outsole Components

The Stratus HK Trainer outsole is designed using a multi-directional lug shape which allows the user with a sense of reassurance with every step on their journey. The green lugs are made with a higher density rubber for longevity and to withstand rugged terrain.

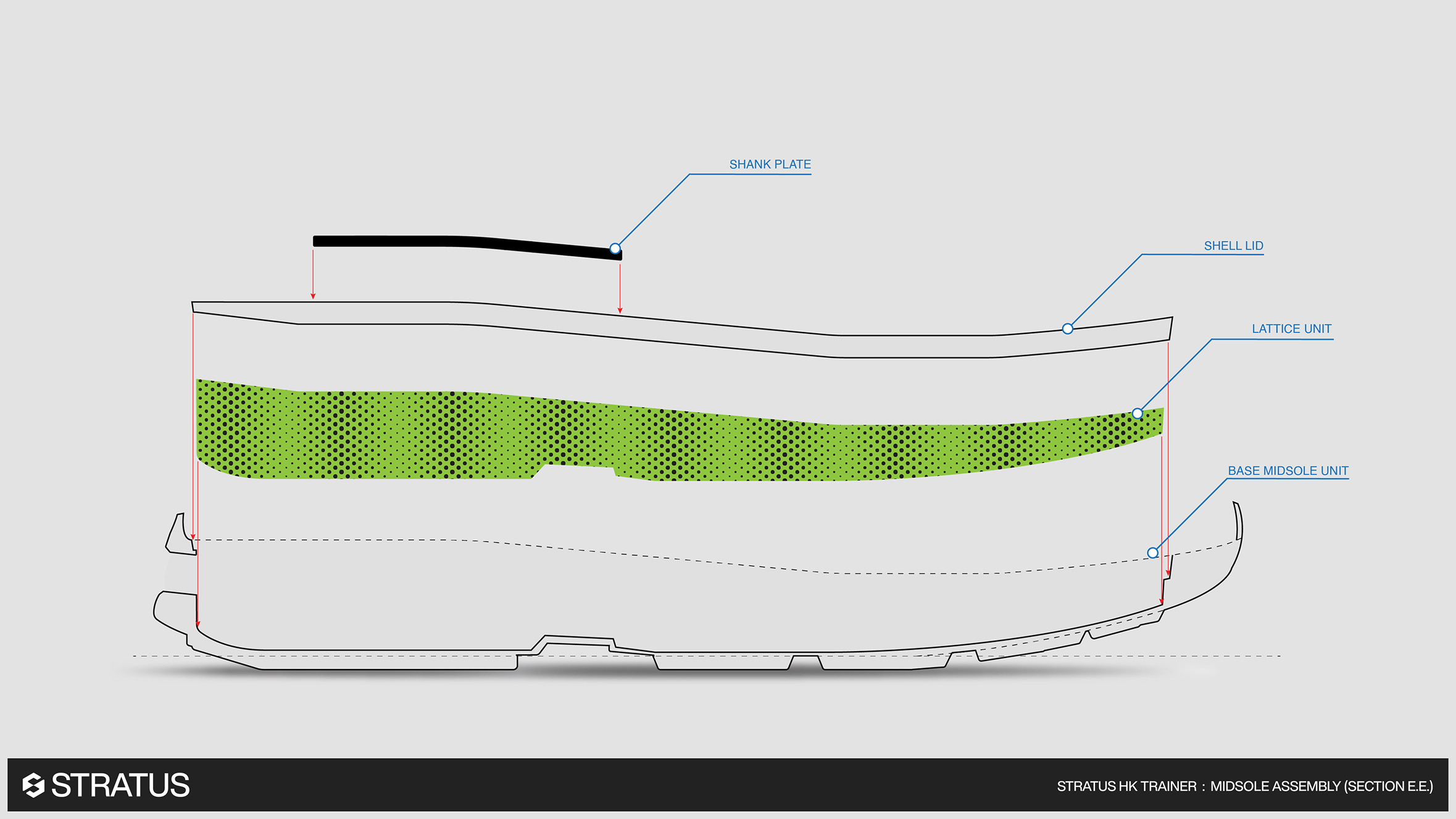

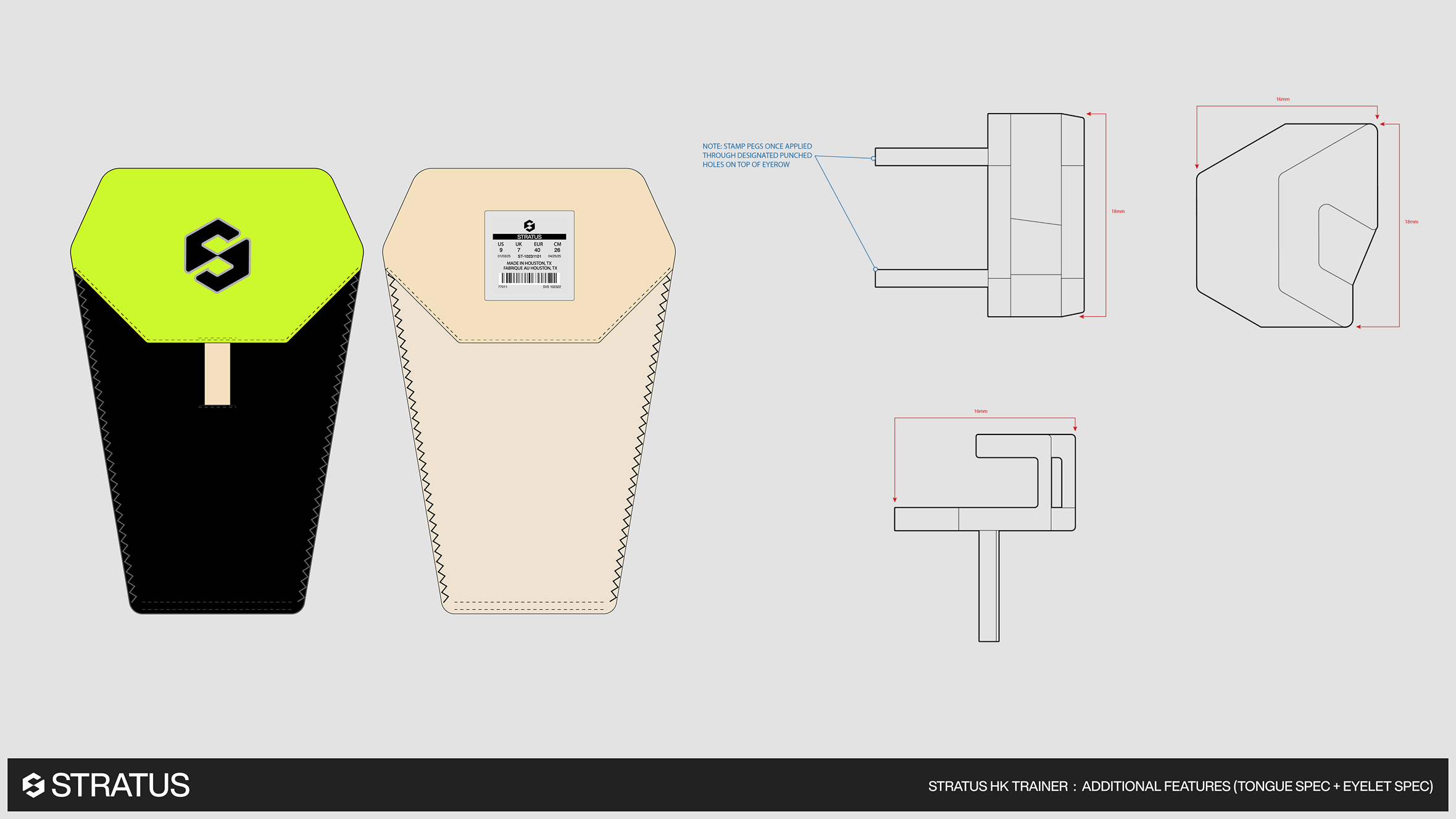

Internal Components

The Stratus HK Trainer has an interior and exterior carbon fiber shank for both propulsion and structural support. The lattice unit is inserted during manufacturing similar to a drop-in midsole with a cap on top. The toe of the shoe features an over-lasted component to eliminate any debris or water from breaching in.